SPECIFICATIONS

Membrane Properties

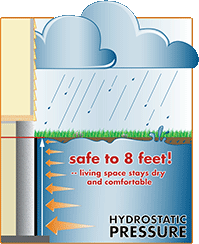

| Resistance to Hydrostatic Head | Results: 8 of water | Method: ASTM D-5385 |

|---|---|---|

| Type | Polymer-enhanced asphalt liquid-applied membrane | |

| Color | Black | |

| Solids | 64% ± 3% [percent by weight] | |

| Density | 8.2 ± .15 lbs/gal | |

| Application | Airless spray | |

| Application Temperature | Minimum 20°F | |

| Application Thickness | 60 mils (wet)1 | |

| Typical Cure Time | 16-24 hrs [under normal conditions] | |

| Crack Bridging Ability | Results: Passes | Method: ASTM C-836 |

| Water Vapor Permeance | Results: <1 perm for 40-mil dry coating (grains/sf/hr) |

Method: ASTM E-96 Wet Method |

| Elongation | Results: >2000% | Method: ASTM D-412 |

| Adhesion to Concrete | Results: Exceeds | Method: ASTM C-836 |

| Resistance to Degradation in Soil | Results: Good | Method: ASTM E-154 |

| Mold Growth and Bacterial Attack | Results: No degradation | Method: ASTM D-3273 ASTM D-3274 |

1 Measured in-place with ASTM D-4414 notch film gauge. Wet 60 mils on notch film gauge. Membrane cures [dries] to 40 mils.

Board Properties

| Type | WARM-N-DRI Foundation Board |

TUFF-N-DRI Barrier Board |

||||

|---|---|---|---|---|---|---|

| Board Size | 4 x 4 4 x 8 | 4 x 4 4 x 8 | ||||

| Board Thickness | 3/4" | 1 3/16" | 2 3/8" | 3/4" | 1 3/16" | 2 3/8" |

| Drainage Ability [Gals/Hr/Lineal Foot]2 | >70 | >110 | >210 | >50 | >80 | >160 |

| Thermal Resistance | R-3 | R-5 | R-10 | R-33 | R-53 | R-103 |

1 Measured in-place with ASTM D-4414 notch film gauge. Wet 60 mils on notch film gauge. Membrane cures [dries] to 40 mils.

TUFF-N-DRI H8 Membrane

Competitive Membrane

With 8 feet of hydrostatic head resistance, TUFF-N-DRI H8 delivers waterproofing protection that reaches the full height of a foundation wall. But competitive products can fail if heavy rains, a failed drainage system or sump pump, excessive winter melting or slow-draining soils produce as little as 12 of hydrostatic pressure.